Powder Coating Equipment Manufacturers in India

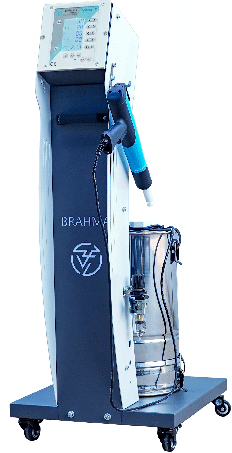

Brahma Fabricon

- Down Draf Wet Type Spray Painting Booth

- Side Draft Closed Chamber Type Spray Painting Booth

- Side Draft Dry Type Liquid Painting Booth

- Conveyorized Powder Coating Booth

- Filter Cartridge Manual Powder Coating Booth

- Manual Powder Coating Booth For Control Panel

Brahma Fabricon is a leading powder coating equipment manufacturer in India, based in Vadodara, Gujarat. As an ISO 9001:2015 certified company, we specialize in high-performance, energy-efficient systems for industries including automotive, furniture, appliances, control panels, aluminium sections, and cleanroom panels. From manual setups to fully automated conveyorized lines, our equipment delivers uniform, durable finishes with minimal waste and maximum productivity.

Flagship – Conveyorized Powder Coating Plants

Our conveyorized powder coating plants are engineered for high-volume, automated production with consistent quality and reduced labor. These turnkey systems synchronize part movement through the entire coating process for superior efficiency.

Key Benefits:

- Automated overhead or chain conveyors for seamless workflow

- Variable speed controls to accommodate diverse part sizes and shapes

- Energy-efficient design reduces power consumption and operational costs

- High transfer efficiency with excellent powder utilization

- Proven performance in projects for control panels, aluminium sections, and cleanroom applications

Advanced Powder Coating Equipments

Complement your line with our precise, user-friendly powder coating guns and automation tools:

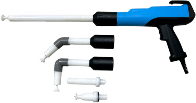

Micro-Static 100

POWDER COATING EQUIPMENT

Lightweight 100 kV detachable cascade system; quick-release connectors, round/flat nozzles; reduces wastage and boosts transfer efficiency.

Quick Release Powder Connector benefits to instant push & pull Powder Hose Inlet & benefits of Minimize Downtime while Powder changing.

Round and flat nozzles for various types of job to avoid access powder wastage.

Electro Pneumatic Control Panel:

- Compact hand carry control panel

- 100% pneumatic parts are very reputed company

available in the entire India and abroad.

Dual-Static 100

Dual-gun setup with smart diagnostics; perfect for touch-ups and detailed work.

Complete control in your hand with “Inbuilt Smart Diagnosis Panel“ Can solve any problems tracking from the panel.

Single-handed operation panel – both guns operate from a common electro-pneumatic panel for quick start.

Lightweight 100 Kv guns with high voltage detachable cascade system.

Ideal for Manual Touch up in Conveyorized Plant with TWO OPERATORS

Opti-Static 100

Highly efficient digital powder coating machine - Digital controls, pre-set programs for flat surfaces, corners, and recoating; ensures uniform thickness.

Easy to Use Even Beginners – The Opti-Static 100 is very easy to operate and impresses with its clear and intuitive display.

Inbuilt 3 Main Pre Set Program For Flat surface, Sharp Corners and Recoating

Can be Programmed individually and can same 99 customized Programme which can be retrieved at anytime.

Improve penetration Reduce Orange peels back ionization and picture frame even with difficult powders.

Inbuilt Digital Valve Precious Flow Ensures precise and reproducible powder output regulations and improve the Film Thickness consistency.

Standard 10 kg 304 Grade Stainless Steel Hoppers protect Powder from the Ambient and gently fluidizes it for and ideal Powder Delivery.

Autoguns & Reciprocator

Variable stroke (1500–2000 mm), programmable movement; cuts labor, improves speed and coating quality.

Reduced labor costs: The reciprocator can be operated by one person, which reduces labor costs.

Improved working conditions: The reciprocator can be used to coat parts in a safe and controlled environment.

If you are looking for a way to improve the quality of your powder coating finishes, increase production output, and reduce labor costs, then a powder coating automatic reciprocator with variable stroke from 1500 to 2000 mm may be the right solution for you.

With Variable Stroke from 1500 – 2000 mm A powder coating automatic reciprocator with variable stroke from 1500 to 2000 mm is a machine used to apply powder coating to parts. The reciprocator moves the parts back and forth through the powder coating booth, ensuring that they are evenly coated. The variable stroke allows the machine to be used with parts of different sizes. Here are some of the features of a powder coating automatic reciprocator with variable stroke from 1500 to 2000 mm:

- Variable stroke: The stroke of the reciprocator can be adjusted from 1500 to 2000 mm, which allows it to be used with parts of different sizes.

- Programmable: The reciprocator can be programmed to move at different speeds and to pause at different points in the stroke. This allows for precise control over the coating process.

- Durable: The reciprocator is made from durable materials that can withstand the harsh conditions of a powder coating booth.

- Easy to use: The reciprocator is easy to set up and operate.

- Efficient: The reciprocator can coat parts quickly and efficiently.

Here are some of the benefits of using a powder coating automatic reciprocator with variable stroke from 1500 to 2000 mm:

- Improved coating quality: The reciprocator ensures that parts are evenly coated, which improves the quality of the finish.

- Increased production: The reciprocator can coat parts quickly and efficiently, which increases production output.

Complete Turnkey Powder Coating Solutions

We provide integrated systems tailored to your factory needs, including full conveyorized lines and supporting equipment for optimal results. All solutions feature:

Custom engineering and layout design

Expert installation, operator training, and after-sales support

Eco-friendly features like high powder recovery and low emissions

Why Choose Brahma Fabricon?

ISO 9001:2015 certified quality & reliability

Local manufacturing & support in Vadodara, Gujarat – quick response across India

Competitive pricing with focus on ROI (lower rejection rates, reduced manpower)

Proven track record in diverse industrial applications

Commitment to durable, high-quality finishes

Frequently Asked Questions

What is the advantage of conveyorized powder coating plants?

They automate the entire process for consistent coating, faster throughput, and significant labor savings compared to manual methods.

Do you customize equipment for specific industries?

Yes, we tailor conveyor speeds, gun settings, and line layouts for control panels, aluminium, furniture, and more.

Where are you located and do you serve nationwide?

We are based in Vadodara, Gujarat and we deliver, install, and support projects pan-India.

How do I get pricing or a site visit?

Contact us below for a no-obligation quote or consultation.

Get In Touch

Ready for efficient powder coating solutions? Reach out today.

Address: 332 Survey Block, Por-Kayavarohan Road, B/S D-Mart Ware House, Ankhi Village, Por, Vadodara, Gujarat – 391243,

Phone: 8320244173/9227534580

Email: powercoatingplants@gmail.com