Powder Coated Equipements

- Down Draf Wet Type Spray Painting Booth

- Side Draft Closed Chamber Type Spray Painting Booth

- Side Draft Dry Type Liquid Painting Booth

- Conveyorized Powder Coating Booth

- Filter Cartridge Manual Powder Coating Booth

- Manual Powder Coating Booth For Control Panel

Powder Coating Equipements

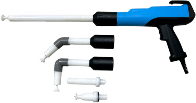

Micro-Static 100

POWDER COATING EQUIPMENT

Light weight 100 kv high voltage detachable cascade system just push and work with reduce wastage and high transfer efficiency.

Quick Release Powder Connector benefits to instant push & pull Powder Hose Inlet & benefits of Minimize Downtime while Powder changing.

Round and flat nozzles for various types of job to avoid access powder wastage.

Electro Pneumatic Control Panel:

• Compact hand carry control panel

• 100% pneumatic parts are very reputed company

available in entire India and abroad.

Dual-Static 100

POWDER COATING EQUIPMENT

Complete control in your hand with “Inbuilt Smart Diagnosis Panel“ Can solve any problems tracking from the panel.

Single-handed operation panel – both guns operate from common electro-pneumatic panel for quick start.

Lightweight 100 Kv guns with high voltage detachable cascade system.

Ideal for Manual Touch up in Conveyorized Plant with TWO OPERATORS

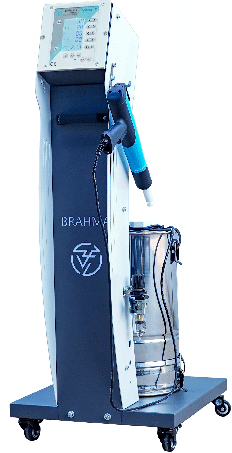

Opti-Static 100

HIGH EFFICIENT DIGITAL POWDER COATING MACHINE

Autoguns & Reciprocator

POWDER COATING EQUIPMENT

- Reduced labor costs: The reciprocator can be operated by one person, which reduces labor costs.

- Improved working conditions: The reciprocator can be used to coat parts in a safe and controlled environment.

If you are looking for a way to improve the quality of your powder coating finishes, increase production output, and reduce labor costs, then a powder coating automatic reciprocator with variable stroke from 1500 to 2000 mm may be the right solution for you.

- Variable stroke: The stroke of the reciprocator can be adjusted from 1500 to 2000 mm, which allows it to be used with parts of different sizes.

- Programmable: The reciprocator can be programmed to move at different speeds and to pause at different points in the stroke. This allows for precise control over the coating process.

- Durable: The reciprocator is made from durable materials that can withstand the harsh conditions of a powder coating booth.

- Easy to use: The reciprocator is easy to set up and operate.

- Efficient: The reciprocator can coat parts quickly and efficiently.

- Improved coating quality: The reciprocator ensures that parts are evenly coated, which improves the quality of the finish.

- Increased production: The reciprocator can coat parts quickly and efficiently, which increases production output.